(BGA/LED SMD Rework System)

HÃNG: SEAMARK ZM

MODEL: ZM-R720

Seamark ZM offers BGA Rework Station since 2005, we have manual, semi-automated and automated bga rework systems with high precision, and user-friendly operation interface, it’s easy to setup and use. Seamark ZM BGA rework station capable of a wide range of board and component including BGA, CSP, QFN, Flip Chips, POP (Package on Package), Micro-SMD (0201, 01005).

ZM-R720/720A BGA/LED SMD Rework System

- Stable and Uniform Hot Air Heating System

- Lower Heater Adjustable

- Carbon Fiber Micro-crystalline Infrared Preheater

- High-Precision PID Temperature Control System

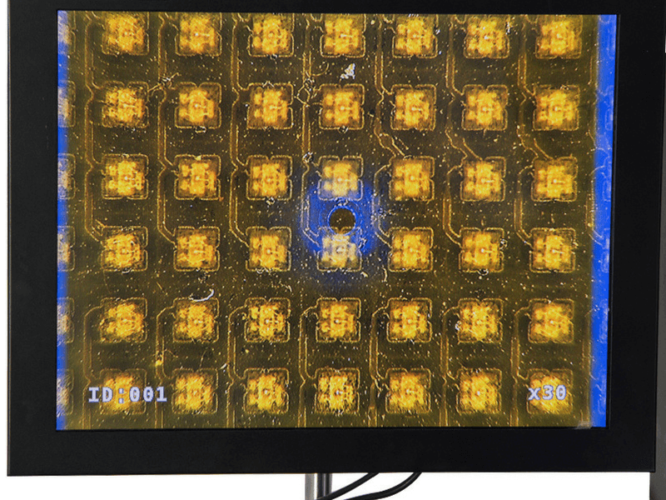

- High-Precision Optical Alignment System with Industrial High-Definition CCD (2MP)

- High-Resolution Touch Screen HMI Interface

- Automatic Placement, Soldering, Desoldering

- Built-In Pressure Testing Device to Protects the PCB

- Real-time Temperature Monitoring and Over-Temperature Protection.

- Emergency Stop Function

- SMD Feeding Device Support (Optional)

- Add a side camera, more clearly observe the rework process(Optional)

Application

Suitable for Normal SMD(BGA, QFP etc.) & Micro-SMD Components Repair, Support P08 Small pitch LED beads, Min. 0.5mm * 0.5mm IC.

Technical Parameters

| Item | ZM-R720A |

|---|---|

| Operation Mode | Automatic / Optical /Touch Panel |

| Voltage/Power | AC220V±10%(110V Optional), 50/60HZ / Top: 1200W, Bottom: 1200W, IR: 3200W |

| Heating Mode | Top/Bottom Nozzle Hot Air, Bottom Plates Infrared |

| Temperature Precision | 2-3 ℃ (1 Sensor Port) |

| Preheat Zone | 280×380mm |

| Optical Alignment Precision | 0.01MM |

| CCD Magnification | 5X~50X |

| LCD Display | 17〞1080P FHD LCD Display |

| For PCB Size/Chip Size | PCB Size: 415*370MM~6*6MM / Chip Size: 0.6*0.6~40*40MM |

| Machine Dimension | L640*W630*H920 (MM) |

| Net Weight | 71KG |

| Standard Wooden Packing | Packing Size: L750*W700*H950 (MM) / G.W: 120KG |