Anish Top Spray Granulator

Anish Pharma Equipment

Model: ATSG

Dry mass is charged into mobile product container .This product container is fitted onto the machine by means of pneumatic pressing device .Fluidization is created by systems induced drought blower .The filtered air passed over by steam heater is induced into product container which in turns creates fluidization effect for the mass .Binder is sprayed from top side (counter current spraying) through spraying system. The continuous fluidization with the help of controlled, filtered hot air removes the moisture from the mass & thus ultimately results in granulation.

Specification of Anish top spray granulator

| Model: ATSG | 5 | 25 | 50 | 125 | 250 | 500 | 800 | 1300 |

| Container Volume in Liters Top spray | 5 | 25 | 50 | 125 | 250 | 500 | 800 | 1300 |

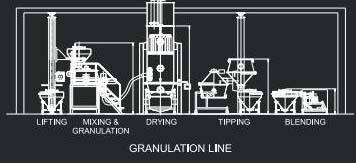

SCHEMATIC LAYOUT

High Shear Mixer Granulation

High Shear Agglomeration by means of either top or bottom driven mixing blades in a close container is a well known processing option in pharma industry.

Agglomeration in the Fluid bed system is a modern & sophisticated method of creating granules from different powders by using liquid as a binder media. The liquid to by sprayed can be either aqueous-Water/ Organic solvents or a binder dissolved solution. The moist granulates are dries & if required, cooled. This results in relatively low mechanical forces in the flued bed so incredibly soluble granules in water. The granule properties can be controlled over a wide range by setting different parameters like Bulk density, Porosity, Size, etc…

———————————————————————————————————————

———————————————————————————————————————

Mọi chi tiết xin liên hệ với chúng tôi:

Công ty TNHH Thương Mại Rồng Tiến

42/14 Nguyễn Hữu Tiến, P. Tây THạnh, Q. Tân Phú, TP HCM

SĐT: 028 3816 4708

email: rongtien@rongtien.com